Integrated Civil Explosive Services

Hongda Civil Explosive Group is composed of 17 specialized participating member enterprises engaged in the research and development, production, distribution, and blasting services of civil explosive equipment. Hongda Civil Explosive Group is a demonstration enterprise for independent innovation in Guangdong Province, with three industry university research bases and teaching practice bases. It has four provincial-level scientific and technological innovation research and development platforms, including the Guangdong Civil Explosive Equipment Engineering Technology Research Center and the Guangdong Mining Civil Explosive Integration Academician Workstation Testing and Analysis Center. A total of nine of its subsidiaries have been awarded the title of high-tech enterprise, seven have been awarded the title of specialized and innovative small and medium-sized enterprise, and nine have been awarded the title of innovative small and medium-sized enterprise. It has won six provincial-level scientific and technological awards and more than 180 national patents.

This sector has taken the lead in achieving intelligent and automated production with less than 3 people in the field of emulsion explosive production, and has been rated as a national demonstration unit for intelligent manufacturing and unmanned promotion in the civil explosive industry; The pioneering liquid mixed expanded ammonium nitrate explosive production line technology has independent intellectual property rights and has transferred more than 20 products nationwide; The DDNP sewage biological treatment technology developed effectively solves the environmental protection problem of water used in the production of detonators and explosives, reaching a leading level in China; The CZED-1 digital electronic detonator and its supporting system developed have achieved full continuity, automation, and full lifecycle control, promoting technological progress in the industry. In the field of engineering blasting services, we have successfully developed the first domestic MEF mobile latex matrix station and BCJ-3 on-site mixed emulsion explosive vehicle in cooperation with Beijing Mining and Metallurgy Research Institute.

In recent years, this sector has capitalized on national policies encouraging horizontal and vertical integration within the civil explosives industry. Through investments and acquisitions, it has gained control over several civil explosives production enterprises across regions such as South China, North China, Northeast China, and Northwest China. Gradually, it has established a strategic layout driven by the dual engines of the civil explosives and the mining services. We are the pioneer in the integrated operation of mining and civil explosives.

The fully automatic production line for electronic detonators has functions such as detonator foot wire processing, bayonet plug injection molding, electronic ignition component welding, product assembly, bagging, boxing, product information generation an

The liquid mixed expanded ammonium nitrate explosive production line adopts the technology of first mixing and then expanding. The oxidant ammonium nitrate is mixed with the combustible compound oil phase in a liquid molecular state and then expanded and

The emulsion explosive production line uses a continuous and automated emulsification process of ammonium nitrate aqueous solution and liquid oil phase material to produce latex matrix, which is then subjected to chemical, physical sensitization or a comb

Industrial electronic detonators are mainly composed of foot wires, electronic delay components, tube shells, reinforced caps, detonating explosives, and explosive charges. The ignition process involves detecting and charging the electronic detonators thr

Utilizing a series of modular mixed explosive vehicles, using on-site mixing or remote distribution methods, to carry out explosive loading and blasting operations for large and medium-sized blasting projects. Compared with packaged explosives, mixed expl

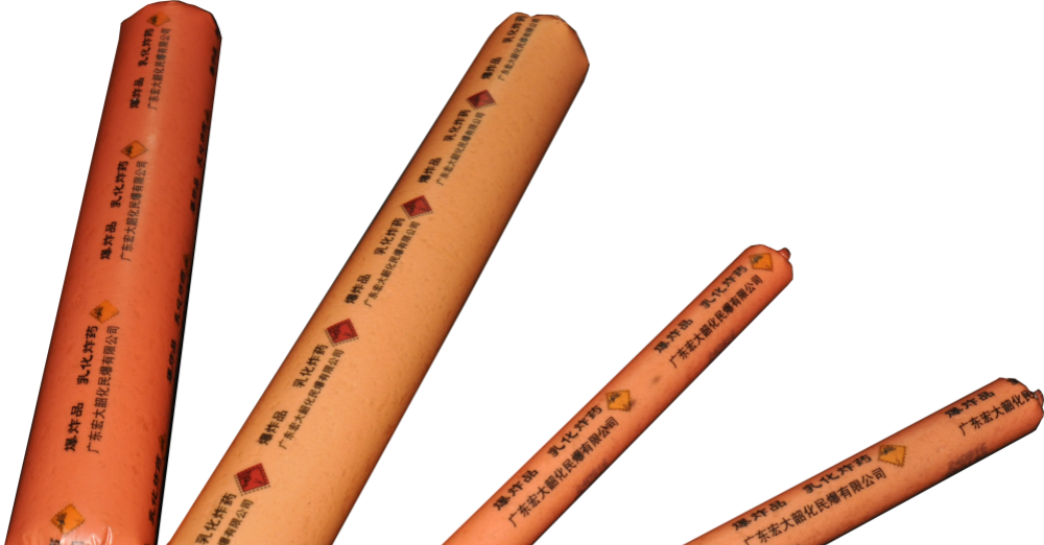

Packaged explosives are usually made by mixing oxidants and combustibles, and the production process includes steps such as raw material mixing, charging, packaging, and storage. Its advantages include easy storage and transportation, convenient use, and

56th Floor, East Tower, Tianying Plaza, Building C3, No. 222-3 Xingmin Road, Tianhe District, Guangzhou City

020-38092888

4th building, No. 5 courtyard, Jindiwei Xin International Center South District, Shengfang Road, Daxing District, Beijing

010-81211111

hdbp@hdbp.com